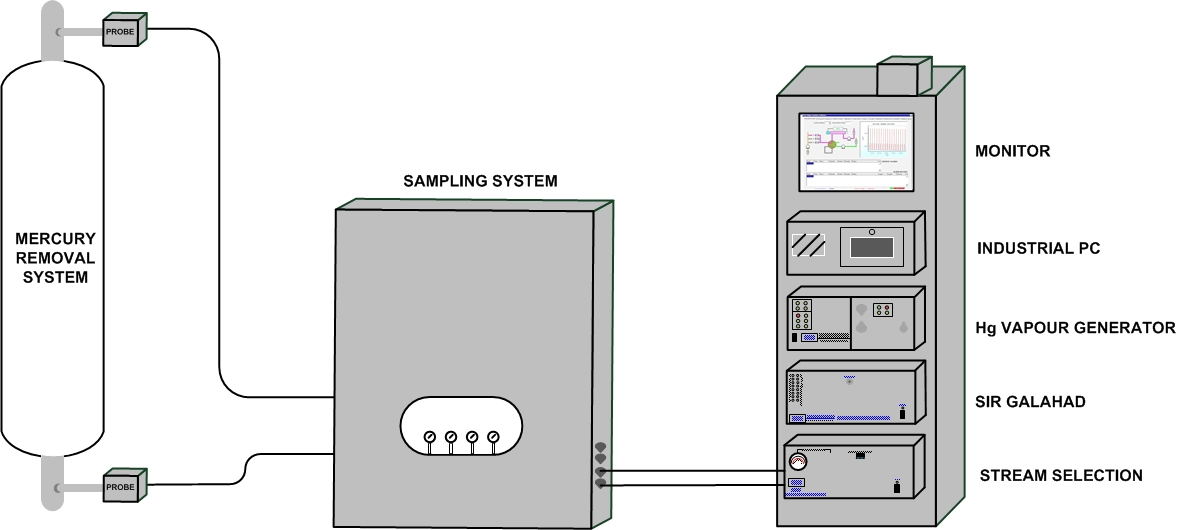

ONLINE MERCURY IN NATURAL GAS SYSTEMS

As most natural gas installations are build to order and have to meet specific requirements, the PSA Online Natural Gas systems are similarly specifically engineered to customer requirements for both measurement and control facilities for the measurement of mercury in natural gas. The Online Natural Gas systems are based on two modules, the PSA 10.54X Sampling System and the PSA 10.670 Process Analyser. These units operating together provide a powerful mercury monitoring system for Natural gas. These modules can utilise optional modules such as Primary Pressure Reduction, Primary Bypass Control or use Automatic Carrier Gas Control to configure a bespoke system. |

|

PSA have designed suitable online sampling systems based on the widely used offline sampling system the PSA 10.547D which ensure that the sample taken is fully representative of the matrix when presented to the measurement device. The PSA 10.54X series of online sampling systems have been designed to operate in hazardous areas using electrical components certified to explosion proof rating and are built to handle an typically 1-8 channels (although 4 streams are normally the maximum in one cabinet). The process analyser section is housed in a purged enclosure which can utilise air or nitrogen purge. The purged enclosure has a controller which only allows power to be applied to the instrument when it is safe to do so and can be constructed to meet NEC, IECEx or ATEX standards. |

|

The heart of the PSA 10.670 Online Analyser is the PSA 10.525 Sir Galahad mercury analyser operating in dual amalgamation mode. The system also contains a stream selection unit (for multi channel operation and automatic calibration), an automatic calibration system PSA 10.536 Hg Vapour Generation and an industrial computer with monitor running the PSA Online Software. The PSA 10.670 used for the measurement of mercury in natural gas by atomic fluorescence follows the ASTM 6350-98 and ISO 6978-2 procedures and is specifically configured for the petrochemical industry. The system can be expanded to simultaneously handle the online analysis of mercury in volatile liquid hydrocarbons and condensates by the addition of the PSA 10.690 Mercury Preconcentration system. P S Analytical have sold large numbers of Sir Galahad systems for the determination of Mercury in Natural Gas to all the oil and gas multinationals, the majority of the field testing companies and many of the mercury removal system suppliers. Many Online Mercury in Natural gas/LNG Systems have been sold worldwide to customers who have multiple systems, many of which handle multiple gas streams. To discuss particular requirements and for more detailed information on the above products, please complete the Information Request Form. |

|