PSA 10.670 MERCURY ANALYSER FOR ONLINE PRESSURISED GASES

The PSA 10.670 is specifically designed to determine total gaseous mercury (TGM) in process gas streams such as natural gas, sour gas, fuel gas, LNG, LPG, butane, ethylene, propylene, hydrogen, carbon dioxide and Syngas. It is also used for measuring total mercury in volatile liquid hydrocarbons and condensates. The system is used in conjunction with a PSA 10.54X Online Sampling system for measuring mercury in pressurized gases or a PSA 10.690 Online Preconcentrator system for measuring mercury in volatile liquid hydrocarbons. Typical Installation - PSA 10.670 Online Mercury Analyser in Cabinet with Sampling System |

|

|

|

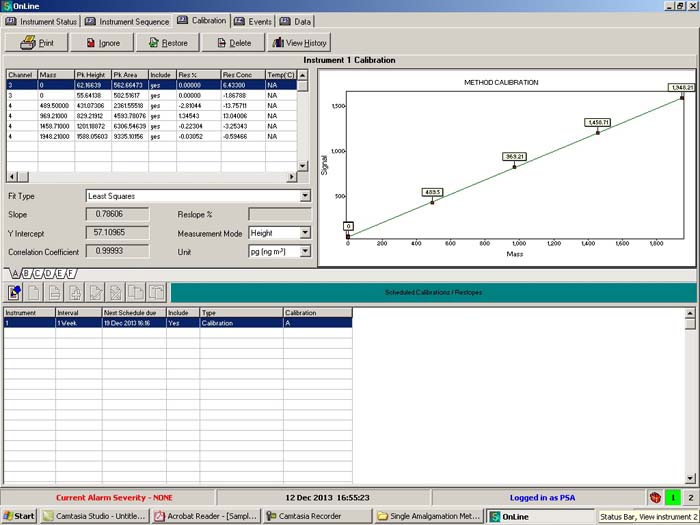

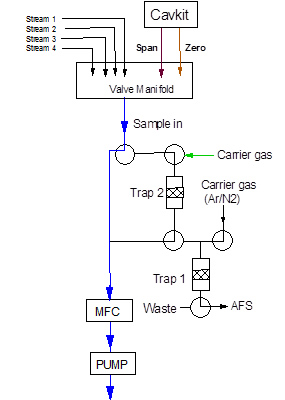

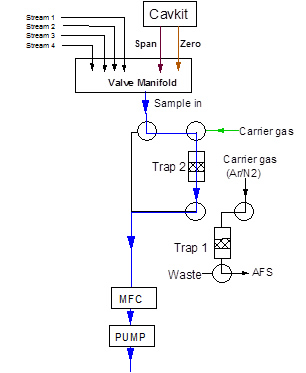

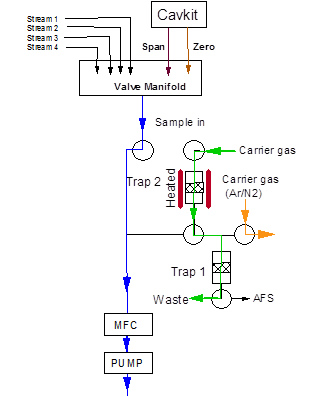

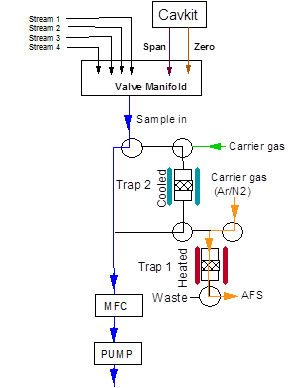

The 10.670 Online Hg AnalyserThe PSA 10.670 Online Analyser used for the measurement of mercury in natural gas by atomic fluorescence follows the ASTM 6350-98 and ISO 6978-2 procedures and is specifically configured for the petrochemical industry. The PSA 10.670 Online Analyser is based on the PSA 10.525 Sir Galahad Mercury Analyser operating in dual amalgamation mode. The system contains a Stream Selector (for multi channel operation and automatic calibration) and an automatic calibration system is based on the PSA 10.536 Mercury Vapour Generator. They Analyser is controlled by a built in industrial computer with monitor running PSA Online Software. The 10.670 can be constructed to meet ATEX, IEC and IECEx Certification, with the addition of a Purged Enclosure. The system may be configured for multiple sample streams. The operation if the system is described below; When a stream is selected the sample gas flows over trap 2 using a vacuum pump and mass flow controller arrangement. The sample flowrate is controlled using a mass flow controller. Once the required amount of sample has passed over trap 2 the mercury collected from the sample is released by thermal desorption into a carrier gas, which transfers the mercury onto trap 1. The mercury on trap 1 is then released by thermal desorption into the AFS detector. In dual amalgamation mode the collection temperature of trap 2 can be controlled, so we can sample the above the dew point of the gas. The mercury Vapour Generator Calibration unit is used to deliver a high span of elemental mercury and blank to the valve manifold so that automated calibration can be achieved. Alternatively the Sir Galahad can be calibrated in an absolute fashion using the vapour injection technique onto trap 1. The process analyser is shown in schematically in Figures 1a-d. (Sir Galahad Analyser Schematics, click to enlarge) |

|

1A - Sample pre-flush |

1B - Sampling onto Trap 2 |

1C - Hg transfer from Trap 2 to Trap 1 |

1D - Analysis |

|

|

|

|

To discus particular requirements and for more detailed information on the above products, please complete the Information Request Form. |

|||